|

|

|||

| Go to page 1~2~3~4~5~6~7~8 [Next] | ||||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Over the years that we have been posting on this forum, there have been a wealth of wonderful shop tips that make life easier for builders in general, including magic builders. Most of these are scattered among the hundreds of topics in "The Workshop".

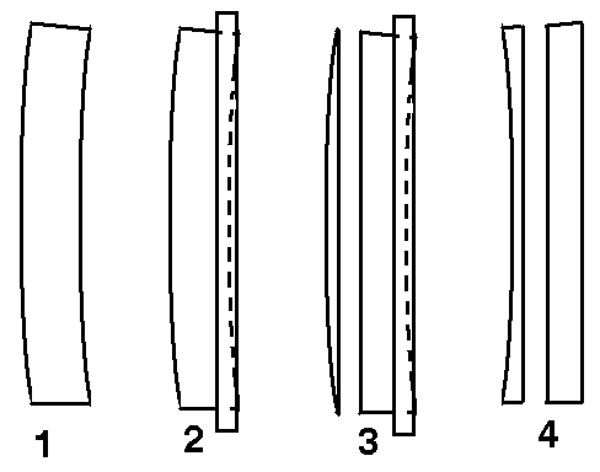

I am starting this thread, as a proposal to post your favorite shop tips here. The tips can be anything you know, that maybe you discovered as a way to simplify a job, or simply give better results. I am also hoping that we can have this thread as a sticky topic... a first for "The Workshop". To begin, here is my first shop tip... This may already be common knowledge among woodworkers, but I had never encountered it before and came up with this solution. I actually discovered this earlier tonight when I wanted to rip a long piece of Walnut and found to my dismay that it had a pronounced crook. A crook is a type of warp in which the faces of the board are flat, but it warps in one direction, much like a curved road. (# 1) It was not going to be possible to cut a straight edge using a rip fence because the direction the wood fed into the blade would change as the curve passed along the fence. The board was considerably longer than the rip fence. So after thinking about this for a minute, I decided to use sort of a surrogate straight edge. I took a piece of wood that I knew had a nice straight edge and taped it on top of the piece of Walnut. I fastened it over the inside edge of the curve, making sure the near and far ends of the Walnut were flush with the edge of the straight board. The center portion of the Walnut curved away from the straight edge of this surrogate board. (# 2) With the boards now joined, I was able to make the cut, using the straight edge of the surrogate board against the fence. This cut a nice straight edge on the opposite edge of the Walnut. (# 3) Once that was done, I detached the surrogate board, as it was no longer needed. The Walnut was flipped over so the newly cut straight edge was against the fence, and the board was run through again, this time being ripped to the width I wanted. (# 4)

~michael baker

The Magic Company |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Next shop tip...

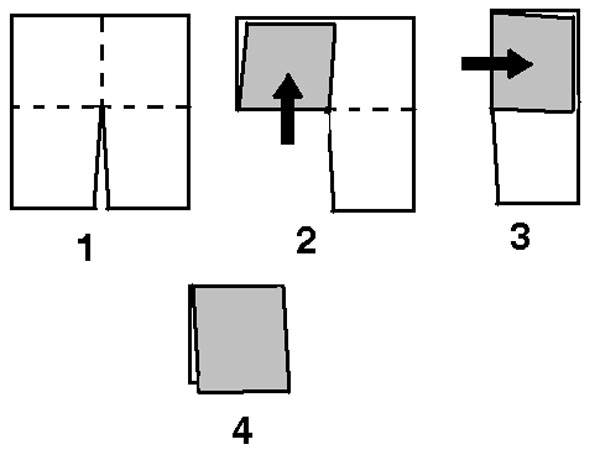

Sometimes, you want to sand without a sanding block. It is usually easier to manipulate the sandpaper, if it is folded in halves or quarters providing a thicker "pad" of sandpaper. It can also be beneficial if your fingers are contacting a grit surface, as the texture will make it less prone to slipping. The problem with folding into quarters is that you will have grit surfaces contacting each other inside the fold. So by the time you get to those fresh surfaces, a lot of the grit has already been worn away through friction. Here is a solution to that problem that will make a piece of sandpaper last a lot longer... Start with a piece of sandpaper 4X the size of the folded piece you'll want to use. Crease it along the horizontal and vertical centers, as shown. Tear or cut from one side to the center, along one of the fold lines. (# 1) Lay the paper with the grit side down, and fold as shown in the next three drawings. (#'s 2-4) Folded in this manner, no two grits surfaces will ever touch each other. As you wear away one panel, just refold so that different surfaces are exposed for use.

~michael baker

The Magic Company |

|||||||||

|

gimpy2 Special user 960 Posts

|

Michael, Great idea for a thread.

Heres a tip for building boxes. This tip speeds up production, gives you a perfect square lid and box and you end up with the grain matched between the lid and box. Build a box with all sides top and bottom in place. just make the box 1/8 an inch taller than you want the end box to be. set the blade on the table saw 1/16 lower than the wall thickness of the box. Now set the fence to what you want the lid to be. Use tape on the corners to avoid split out. Now run the box on all four sides to the fence. next trim the lid free from the box with a hand saw and sand or plane off the exess. Even if the box was built out of square the lid fits perfect.

Gimpy

www.gimpysmagic.com |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Thanks, Gimpy! That's how I make boxes, and the tip on cutting a shallow pass is really good. If the blade is set for too deep a cut, it can really do some damage to the adjacent sides, especially if the blade is even just a hair off 90 degrees.

The idea for tape is also good, and worthy of its own inclusion. So... Another tip-top tape tip... Use masking tape on the exit side (the underside) of wood you plan to run through a table saw. This is especially true is you are using thin plywoods, or other wood prone to chip-out and tearing. Even a zero clearance blade insert can benefit from this. It also helps to run the wood through the saw with what will be the visible face up as it passes through the blade. This way, even minor tear-out will end up on the inside of the box. In the case of rabbet joints, as I use, any chipped edges will be buried inside the joint. It can be very difficult to mend chipped outside corners. Another use for tape... Let's say you have a piece that needs edge sanding. Taking off too little is not a problem, but taking off too much is. Sometimes one or both ends will drop off. Sometimes you find you've sanded a dip in the center of the edge. Mark the line where you want to stop with a strip of tape. This will give you a witness mark that is very easy to see. Just sand right up to the edge of the tape and you've got it! Yet one more use for tape... If you've ever had small pieces to spray paint, you may have found that the force of the spray will blow the piece off the table. I take a length of tape and position it on the table or painting tray, so the sticky side is up. Use a couple more pieces to tape down the ends and you have a nice strip of sticky surface that you can stick the small parts to. Then just spray away!

~michael baker

The Magic Company |

|||||||||

|

Dr_J_Ayala Inner circle In search of Vlad Dracul and his 2169 Posts

|

Indeed Michael - a very fine idea for a topic!

To start my contributions off - most of which will refer to hand-worked (read: without power tools) projects: If you have an edge on a piece of wood that you have finished planing and it is ready for sanding, still having some slight high spots here and there, color those high spots with a graphite pencil and sand away carefully until the graphite is gone. Check occasionally to make sure you do not go too far down, and repeat as needed until you get an even surface. Another easy way to find those high spots: Use two 1/4 inch-thick boards as wide and long as you need them to be, and screw them together in an 'L' shape - a 90 degree angle. These must be perfectly square. Lay this on a table and spread powdered graphite along the bottom board where the two boards meet. Place the width of the board with the high spots against the vertical board of the cradle, making sure the rough edge is in the graphite. Rub the board back and forth a few times and the high spots will pick up the graphite, letting you know where you have to sand. I hope this is not too confusing and that the drawing helps. It may sound like a lot of work, but to a minimalist woodworker who does not have a lot of tools, it just may be a serviceable solution. Click here to view attached image. |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Great tip, Dr. J! Thanks!

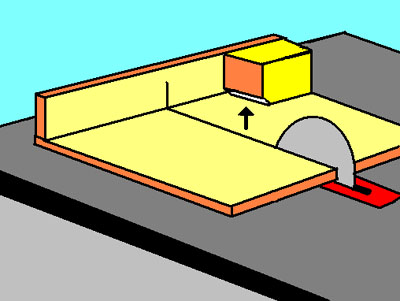

Here's a special jig that may be useful to some... Magicians like to use small wooden boxes, associated with cards, coins, rings, etc. Making these boxes can be a bit tricky because of their small size. Most clamps are too large for the project at hand. In order to easily glue up things like coin boxes, Lippincott Boxes, etc. I made a simple jig as seen in the photos below. It is a simple block of wood with the outside dimensions (length and width) equal to the inside dimensions of the box. Quite often, boxes this small are assembled with simple glued butt joints. The problem with this type of joint is that the pieces do not automatically lock themselves together as they somewhat do with rabbets, dovetails, etc. Assembling them can be like trying to manipulate a jellyfish. With this jig, the pieces (minus the top are formed around the jig, and pressure from the outside holds them perfectly square. In some cases, I use CA glue with an accelerator. I use the thick CA as it has a slower set time. It is possible to run a bead of glue along each area where the joints must be made. The pieces are then assembled around the jig, held in place with the fingers (avoiding the glue) and the accelerator sprayed on to quickly dry the glue. It is also possible to use regular wood glue, and once the pieces are assembled around the jig, they can be held securely with a rubber band or two. You can assemble miter joints the same way. Notice that the jig has all edges and corners sanded off. This is so you do not glue the jig inside the box, should a small amount of glue seep out. The screw in the top serves as a handle to more easily pull the jig from the box when you are done. You can later glue on a top if making a box as mentioned above by Gimpy.

~michael baker

The Magic Company |

|||||||||

|

gimpy2 Special user 960 Posts

|

Tape is also great for holding hardware in place. Tape the piece of hardware in place then use a self centring bit to drill pilot holes through the hardware. Install enough screws to hold it in place then remove the tape and install the rest of the screws. The tape not only gives you straight instalation it gives you an extra hand to work with.

Gimpy

www.gimpysmagic.com |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

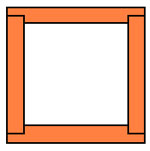

Here's a good idea for gluing up boxes maybe 8" or less. Let's say you are gluing up a six-sided box that has interlocking joints, like rabbets (as seen in the drawing). You may not want to use screws or brads, and attaching clamps in all directions can be awkward, if not impossible. Keep a big bag of different sized rubber bands on hand. Gather several of them that will work for the project at hand, and when you assemble the glue joints, wrap the bands around the box in every possible direction. They will hold everything nice and tight until the glue dries. The interlocking joints will keep everything square.

Note: The drawing shows a top view of the four sides. The top and bottom would be rabbeted on all four edges, and fit like a bottle stopper in the well formed by the sides.

~michael baker

The Magic Company |

|||||||||

|

gimpy2 Special user 960 Posts

|

Newbies sometimes have a hard time cutting straight with a circular saw. For a nice cut heres some tips.

Start with a dark but thin line. don't try to split the line with the blade and don't keep your eye on the guard. Instead keep your eye on the spinning blade and try to shave the side of the line. A straight edge to guide the saw is great for long cuts. you don't need to buy one, a level clamped in place has always worked for me When cross cutting plywood. Tape the the area before you mark. Make your line then score the line with a utility knife before cutting.

Gimpy

www.gimpysmagic.com |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

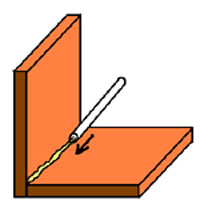

Cutting with a table saw sled or a miter saw often requires the use of a stop block. This is especially useful when making multiple, identical cuts.

Problem: Saw dust can build up in the corner and keep the successive pieces from butting fully against the stop block. This can sometimes blow a cut by as much as 1/8". Solution: Undercut the stop block, so sawdust has an escape route. (Indicated by the arrow in the drawing.) Of course, you'll have to periodically brush it out, and be sure the wood you are cutting is not so thin as to slide under the stop block.

~michael baker

The Magic Company |

|||||||||

|

AGMagic Special user Cailf. 775 Posts

|

Quote:

On 2011-12-02 10:51, Michael Baker wrote: Michael, Here is an idea to make assembly of small boxes easier. Place a long piece of masking tape sticky side up next to the fence of your table saw. While pushing them against the fence, place the pieces (sides) of the box end to end on the tape in the order that you want them glued up. Roll the pieces on the tape up to form the box to check for fit. If the top and bottom of the box are captive in dados, make sure they are in place and fit properly. Unroll the box, add glue, reroll the box and add rubber bands as suggested. Using the tape will hold everything together and in place until the rubber band clamps are added.

Tim Silver - http://www.facebook.com/pages/Magic-Woodshop/122578214436546

I know you believe you understand what you think I said, but I am not sure you realize that what you heard is not what I meant. Visualize Whirled Peas! |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Good one Tim! I have seen this idea done with mitered corners, as they are really hard to glue-up.

~michael baker

The Magic Company |

|||||||||

|

chill Veteran user colorado, usa 385 Posts

|

And don't forget to measure your diagonals to insure the corners of the box are square.

I spent most of my money on magic and women, the rest i just wasted

|

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Yes, sir! I've made a few unintentional diamond-shaped boxes in the past! Those inside dimension glue-up jigs I mentioned earlier solved the problem for small boxes. I also use them for boxes as large as card boxes, because they absolutely have to be perfectly square. But, they are not any good for six-sided glue-ups, and impractical for large boxes. For these, and things like picture frames, measuring the diagonals is a quick way to head off trouble!

~michael baker

The Magic Company |

|||||||||

|

Wizard of Oz Inner circle Most people wish I didn't have 5155 Posts

|

Wow. I've been reading these posts and have loved them. As a collector, this insight into what builders and creators go through into making magic real makes me appreciate my collection so much more. I wish everyone could see that you are making these beautiful pieces of magic out of love for the art of magic...verses profit...of which there can't be much. The time it must take to create these beautiful pieces must be extensive, and for the most part, unseen and unappreciated.

These dialogues are helpful for collectors like me, who value what you do...and now...value it even more. My sincere appreciation for keeping our fine art alive and well...

Pay no attention to that man behind the curtain.

|

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

I posted this on another thread some time ago, but it should be here, too...

When you glue-up a joint, there is often a bit of glue that will squeeze out at the joint. Naturally, you want to wipe this away. If this is on an inside corner, it can be a bit difficult to get a rag or paper towel to get all the way in there, and you usually end up smearing the glue all over the place in the process. Here's the fix... Keep a few plastic drinking straws on hand, and use those like little scrapers. If you push the straw into the corner and run it down the joint, not only will it scrape away the glue, the glue will go up into the straw, where it can be easily disposed of.

~michael baker

The Magic Company |

|||||||||

|

gimpy2 Special user 960 Posts

|

Michael,

I saw this tip when you posted it before and had meant to thank you. I build a prop that requiers metal lap joints that are held by epoxy. This is a great way to clean up the sticky goo that squeezes out. The joints turn out perfect every time. GREAT TIP!

Gimpy

www.gimpysmagic.com |

|||||||||

|

AGMagic Special user Cailf. 775 Posts

|

Quote:

On 2011-12-02 12:53, gimpy2 wrote: Levels work great for this but I saw a jig in a wood working magazine a while back that is even easier. use a piece of hardboard (masonite) that is about 12" wide and as long as you need it to be (mine is 8 feet) and screw a straight piece of wood or aluminum to the center of the hardboard. Now use the installed straight edge and your circular saw to cut off the excess hardboard. You now have a straight edge on the hardboard that can be set to the exact measurement on any piece of sheet goods that you want to cut. You don't have to account for the distance between the side of the shoe and where the blade will cut. This will also help with clamping as the clamps can be on the other side of the straight edge so the saw won't hit them. I have two different circular saws so I turned the jig around and cut off the opposite side with the other saw. Now I have 1 jig that works for either saw.

Tim Silver - http://www.facebook.com/pages/Magic-Woodshop/122578214436546

I know you believe you understand what you think I said, but I am not sure you realize that what you heard is not what I meant. Visualize Whirled Peas! |

|||||||||

|

AGMagic Special user Cailf. 775 Posts

|

Another thought on cutting sheet goods; get a large piece of 1-1/2" to 3" thick flat styrofoam and lay it on the ground or your bench and put the piece to be cut on top of it. Set the blad height (depth of cut) on your circular saw so it just cuts through the sheet of material you are cutting. The styrofoam will protect your saw blade (or the bench beneath it) and will support the workpiece completely for a smooth cut...and it is re-useable.

Tim Silver - http://www.facebook.com/pages/Magic-Woodshop/122578214436546

I know you believe you understand what you think I said, but I am not sure you realize that what you heard is not what I meant. Visualize Whirled Peas! |

|||||||||

|

AGMagic Special user Cailf. 775 Posts

|

Here is a tip that I sometimes forget to do and always regret it. Sand the surfaces of anything you are building BEFORE you assemble it. It is much easier to sand flat stock and there are no inside corners to deal with. Any necessary touch-ups after assembly are usually quick & simple to deal with. Just be sure not to round any edges while you sand. To keep this from happening, place a matching piece of stock next to the piece you are sanding so the edges of both pieces stay flat & square.

Tim Silver - http://www.facebook.com/pages/Magic-Woodshop/122578214436546

I know you believe you understand what you think I said, but I am not sure you realize that what you heard is not what I meant. Visualize Whirled Peas! |

|||||||||

| The Magic Cafe Forum Index » » The workshop » » Workshop Tips (18 Likes) | ||||||||||

| Go to page 1~2~3~4~5~6~7~8 [Next] | ||||||||||

| [ Top of Page ] |

|

All content & postings Copyright © 2001-2024 Steve Brooks. All Rights Reserved. This page was created in 0.08 seconds requiring 5 database queries. |

|

The views and comments expressed on The Magic Café are not necessarily those of The Magic Café, Steve Brooks, or Steve Brooks Magic. > Privacy Statement <

|